Process

Integrated System of Production—from Design to Tryouts

We have integrated our in-house production of metal molds, allowing us to meet the needs of our customers at an extremely high level in terms of quality, cost, and delivery time. We have built a system of production that integrates everything in-house, from meetings with customers, to 3D solid design using CAE, full mold casting, machining/finishing/assembly performed by expert engineers, and tryouts that more closely match the environments of our customers. We manufacture metal molds to meet the quality, cost, and delivery time needs of our customers.

-

1

- Product Data

- Design data for the newly developed body is received from the customer.

-

2

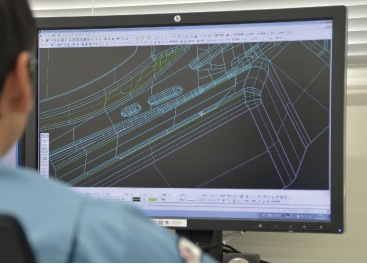

- CAE Modeling

- The data is examined, repaired, and edited based on the design data that was received, then a CAE model is created.

-

3

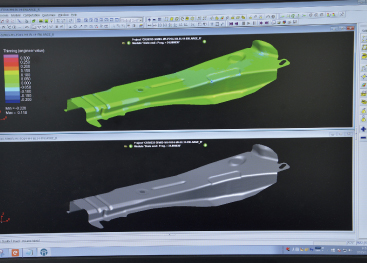

- Mold Simulation

- CAE analysis is used to perform a molding simulation (to check ahead of time for panel cracks and folds). Improved elements are inserted and another survey is conducted.

-

4

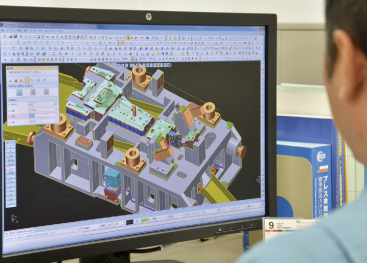

- Metal Mold Design

- After surveying the molding simulation, 3D solid CAD is used to design the metal mold.

-

5

- NC Data Creation

- NC data for metal mold machining is created from the 3D design data.

-

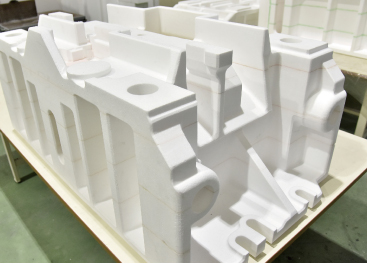

6

- Full Mold Casting

- A full mold is cast with Styrofoam.

-

7

- Machining

- Machining data created with CAD/CAM is used to perform machining with an NC machine tool.

-

8

- Finishing

- Once all machining is complete, the surface precision is measured. Manual grinding is used to finely adjust differences from the design data.

-

9

- Assembly

- Machined parts are assembled by hand into the metal mold.

-

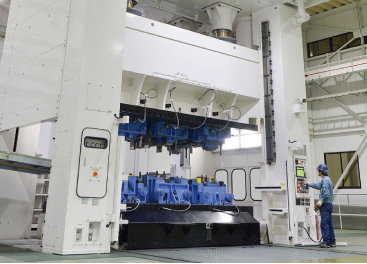

10

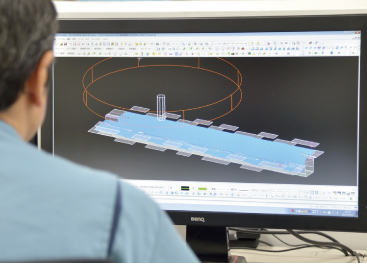

- Tryout

- Prototype metal molds are press machined and tested in an environment closely matching the customer environment.

-

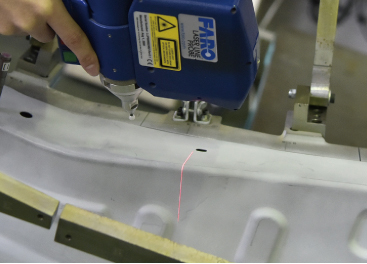

11

- Panel Measurement/Analysis

- The free curved surface shapes of the machined parts are measured with a 3D measuring machine. The actual measurements are compared with the 3D surface model, and a pass/fail decision is made based on the tolerance information.

-

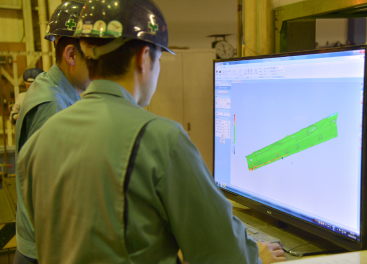

12

- Adjustment

- The metal mold precision is adjusted based on the measurements, the CAM model is updated, and then the NC data is updated. Machining is performed again to bring the product to completion.

-

13

- Shipment

- Only those metal molds that pass our strict quality inspections are shipped to customers.